Silicones

ADDITION SILICONES

Zhermack supplies RTV2 poly addition silicone rubbers (with platinum catalyst) for a wide range

of industrial applications: mold making, jewellery, rapid prototyping, vacuum infusion process,

special effects & body casting, master mold and pad printing.

The RTV2 silicones are available in 1:1 mixing ratio (weight)

PRODUCT BENEFITS

• Dimensional stability

• Ease of use

• High mechanical properties

• High ability to reproduce the details

• Not dangerous for the operator’s

health

• Durability

• Outstanding resistance to gypsums, to

common casting resins and coatings.

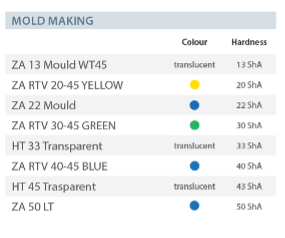

1. MOLD MAKING

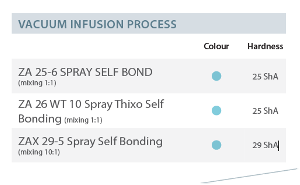

2. VACUUM INFUSION PROCESS

Zhermack range of silicone rubbers is specially formulated for use in the vacuum bagging processes now common in many areas of industry (automotive, marine, etc.).

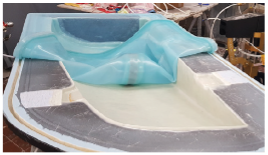

Vacuum bagging is an increasingly common process in composite production. It uses an RTV2 poly addition silicone rubber bag to press elements into shape against the surface of a mould. Vacuum is used both to form the composite material and to draw in the resin that impregnates it. Molds for vacuum bags in silicone rubber

can be reused several times without compromising a perfect fit surface finish to the formed part.

PRODUCT BENEFITS

- High mechanical characteristics

- High dimensional stability

- Self bonding properties (a second layer can be cast within 24 h after casting the first layer)

- Good chemical resistance against polyester, vinylester, etc

THE RANGE

1:1 mixing ratio

- Silicone rubber in liquid version with a hardness of 25 shA and a viscosity that allows to use it with a mixersprayer

- Silicone rubber in thixo version with a hardness of 25 shA as well and is slightly thixotropic and therefore ideal for application by spray and brush

10:1 mixing ratio

- Silicone rubber in liquid version with a hardness of 29 shA

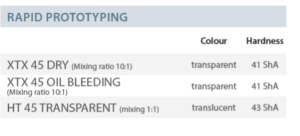

3. RAPID PROTOTYPING

Zhermack’s offer for rapid prototyping applications is the dedicated transparent materials with appropriate hardness of 42 shA in DRY and OIL BLEEDING versions (for increased resistance to particularly aggressive substances like PU resins). Furthermore, is available a translucent silicone rubbers with low viscosity and high tear resistance for the prototyping of small, precision parts.

Silicone rubber moulds are often used to make prototypes of new products. Stereolithographic masters are used to create silicone rubber moulds, using suitable thermosetting resins. The mechanical and thermal properties of these resins are similar to those of the thermoplastic materials used in the production of the finished part.

This means that prototypes are not only faithful reproductions of the original master, but can also be used for functional tests, and provide a valid basis for preliminary sample testing

4. JEWELLERY

Zhermack RTV2 poly addition silicone rubbers are particularly suited to the lost wax casting process commonly used in the jewellery sector. Silicone rubbers can be used to reproduce a large number of copies from an original master.

They allow the tiniest details to be copied faithfully, facilitate finishing and are highly compatible with the materials typically used in jewellery.

The high dimensional stability of Zhermack silicone rubbers’ makes them the ideal solution for luxury jewellery artifact, where the highest standards of quality are demanded. Moulds can be used for over 20 years if properly preserved.

Zhermack silicone rubbers are available in a choice of colours: clear (for users who prefer to see the master object inside the silicon rubber during the cutting phase) and coloured (for more expert users).

PRODUCT BENEFITS:

- Low viscosity for very precise details

- Molds ready in 3h30 ‘at 23 ° C

- High dimensional stability

- High mechanical properties that allow a high

number of copies

- Durability

- Precision in reproduction

CONDENSATION SILICONES

- Self-degassing

- High mechanical properties

- High details reproduction

- Durability

SOLUTIONS FOR INDUSTRIAL APPLICATIONS

RTV-2 Silicone rubbers and Alginates for body casting

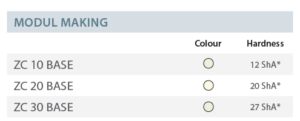

MOLD MAKING

- Technique used for the reproduction of high quality replicas.

- RTV-2 silicone rubbers guarantee maximum dimensional stability in time with high mechanical characteristics and high elasticity over time.

- Fields of application:

- oart ceramic

- oconcrete moulding

- oporcelains

- omodel-making

- osanitary wear

- oart/restoration

- oindustrial moulding

- candle production and many others.

MOLD MAKING | Step by step

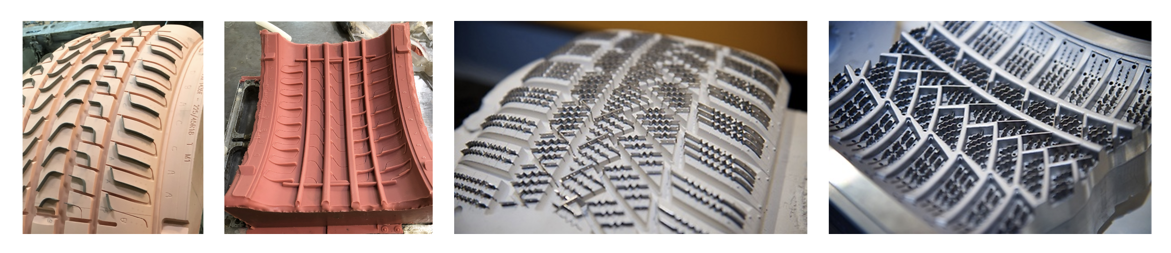

TIRE PRODUCTION PROCESS

Tire moulds used in the curing process are among the most important aspects in the manufacture of premium tires. Due to their complex tread structures, winter tires require a very precise mould (“tread negative”) for the curing process.

Key benefits:

- Very high dimensional stability

- High elasticity

- Very low viscosity to replicate tire thin details

- Chemically resistant to main inhibition

- The color allow to check the product details

TIRE PRODUCTION PROCESS

Reusable membrane for

VACUUM INFUSION PROCESS

The silicone reusable membrane can be used many times, reducing waste materials.

Zhermack offer sprayable and brushable silicones.

Product benefits:

High mechanical characteristics

- High dimensional stability

- Self bonding properties (a second layer can be cast within 24 h after casting the first layer)

- Good chemical resistance against polyester, vinylester, etc

- Perfect surfaces in both side of the mold

Translucent product to recognize the filling of the resin

NOTE: the suggestion is to keep thickness of 3-3,5 mm to allowthe styrene to go through the membrane and increase the number of parts to reproduce

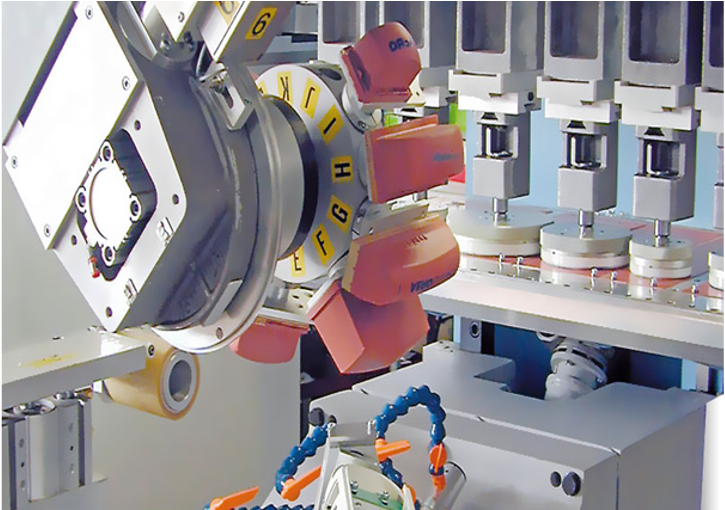

PAD PRINTING

Pad printing is used for the transfer of decoration onto different types of objects. Used in industries that include automotive, electronics, appliances, toys, etc.

The properties of the silicone pad enable it to transfer the image up from a flat plane to a variety of surfaces. RTV-2 silicone rubbers offer high mechanical resistance and excellent elastic return too.

PAD PRINTING | Step by step