Bone China Raw Materials

Global & Darling Ingredients

- Global Ceramic Materials Ltd (GCM) is a subsidiary of Darling Ingredients International (DII), Irving, Texas, USA

- DII involved in processing of and food waste products in to added value markets

- DII Annual Turnover USD 730 Million (2022)

- Over 260 plants world-wide processing in excess of 11 Million Tonnes of Raw Material in to over 145 innovative & sustainable products

Global Ceramic Materials (GCM)

- GCM involved in the processing of natural calcium phosphate and other minerals for use in ceramic and foundry sectors.

- GCM also supply prepared bone china body clays to the tableware sector as filtercake, pug roll and spray dried granulate.

- Customers include Villeroy & Boch, Royal Doulton, Wedgwood, Noritake, Narumi, RAK Porcelain plus many other leading brands.

- GCM process in excess of 10,000 Tonnes of Natural Calcium Phosphate annually

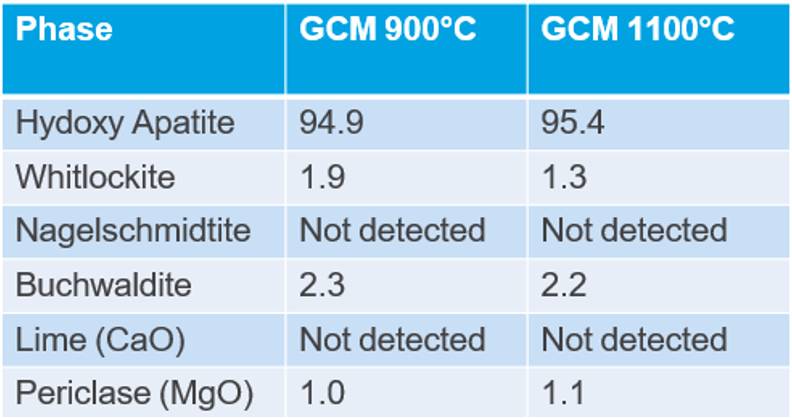

Global Ceramic Materials (GCM) – Calcium Phosphate

- Natural calcium phosphate in the form of the mineral hydroxyapatite

- Used a primary ingredient in bone china (45-50%) giving whiteness, translucency and high fired strength (Wet Ball Milled product used)

- Used as an additive in fine china (5-10%) formulations to enhance whiteness, translucency and fired strength (Wet or Dry Milled)

- Used as a mould coating/ mould release agent in the copper and aluminium foundry sectors (Dry Milled powder used)

- Bone China – requires wet milled calcium phosphate to generate

rounded particles and therefore help plasticity due

to low clay content - Fine China – A cheaper dry milled calcium phosphate can be used

as plasticity primarily coming from kaolins & ball clays.

Fine China

- Prior to bone china being developed, fine china was being produced in the UK and was known as “Parian body”.

- Parian Consisted of Kaolin, Cornish Stone and small additions of Ball Clay

- Cornish Stone was a type of Siliceous Feldspar and found close to the kaolin deposit

- Granite undergoes geo-thermal actions that transforms the granite in to feldspar and then kaolinite, with Cornish Stone being the feldspathic mineral

- The fired colour of fine china is determined by its Iron Oxide (Fe2O3) content

- Therefore white firing kaolins are required (AKW/ Halloysite/ KaoPearl)

- Translucency can be quite orange in colour due to the Fe2O3 content

Traditionally a formulation can be along the following lines;

- 40-45% Kaolin Mixture (Kaolins & possibly Halloysite)

- 4-5% White Firing Ball Clay

- 18-23% Feldspar (Na, K or combination)

- 15-20% Quartz

How does Hydroxyapatite help whiteness?

- The reaction which occurs when a calcium phosphate containing body is fired to 1220-1250°C is as follows

- Hydroxyapatite reacts with kaolinite to produce tri-calcium orthophopshate (TCP), anorthite and water

- 3Ca10(PO4)6(OH)2 + 6[Al2O32SiO2] = 6[CaOAl2O32SiO2] + 8(Ca3(PO4)2 + H2O Hydroxyapatite Kaolin Tri-Calcium Anorthite Water Orthophopshate

- It is the TCP and Anorthite that generate the whiteness

How does Hydroxyapatite help firing?

- When calcium phosphate in the form of hydroxyapatite is added to a body clay it can act as a flux (feldspar) or as a refractory depending on the proportion of hydroxyapatite added, and on the other materials present.

Josiah Spode, when developing bone china probably knew that small amounts of hydroxyapatite added to a porcelain body acted as a flux. He may have found that by increasing the amount of bone he came to a point (approaching a eutectic) beyond which its effect was reversed, bone then becoming a refractory. This is certainly true when the content is increased as the fluxing properties change to refractory.

Asian Fine China

- South East Asian Market requires very white / strong HORECA fine china formulations and therefore add calcium phosphate and alumina

- 4-5% Calcium Phosphate (Bone Ash)

- 40-45% Kaolin Mixture (Kaolins & possibly Halloysite)

- 4-5% White Firing Ball Clay

- 15% Potassium Feldspar

- 7-13% Alumina

- 15-20% Quartz

- Calcium Phosphate ‘bleaches’ the body = whiter/ enhanced translucency/ increased fired strength

- Alumina reduces thermal expansion/ increases fired strength/ thermal shock

Calculating the Calcium Phosphate % from XRF

1. Measure the chemical composition of the un-fired body by XRF

2. For hydroxyapatite to be present there must be sufficient CaO, P2O5 and

H2O present and in the correct molecular ratio.3. The Hydroxyapatite value is calculated from the P2O5 content figure in the

XRF analysis, using the respective molecular weights because P2O5 is

present in Hydroxyapatite but not in kaolin, quartz or feldspar4. A worked example using the previous XRF analysis is as follows;

P2O5 Content (by XRF) = 2.08%

HYA/P2O5 Molecular Ratio = 2.359

HYA Content = 4.9%

Excess CaO and H2O confirmed as being present in the XRF analysis

Bone China

- First developed 1789 – Josiah Spode

- 45-50% Calcium Phosphate (Bone Ash)

- 25-30% Kaolin (China Clay)

- 20-25% Flux (Mix of Na, K Feldspar / Quartz)

- Until recently most recipes ≥ 45% Calcium Phosphate

- Governed by BS5416:1990 and EN1900

- ≥35% Tricalcium Orthophosphate (TCP)

- Natural & Chemical Calcium Phosphate used but natural is technically superior.

Natural Calcium Phosphate

- Generated from a natural calcium phosphate source that is extremely consistent. Organic contaminants removed using hot water, autoclave and rotary kiln to leave an almost pure hydroxyapatite mineral.

- Demonstrates consistency of a natural calcium phosphate when heated to increasing temperature. Creates a stable body formula

Natural Calcium Phosphate – Lower Sagging

| Test | Temperature (°C) | Synthetic CP Body | Natural CP Body |

| Water Absorption | 1250 | 0.04 | 0.08 |

| (%) | 1260 | 0.03 | 0.05 |

| 1270 | 0.03 | 0.04 | |

| Fired Bulk Density | 1250 | 2.59 | 2.59 |

| (g/cm3) | 1260 | 2.59 | 2.60 |

| 1270 | 2.57 | 2.58 | |

| Sagging | 1250 | 6.0 | 2.7 |

| (mm) | 1260 | 8.0 | 3.9 |

| 1270 | 11.1 | 5.0 | |

| Whiteness | 1250 | 94.9 | 93.4 |

| 1260 | 94.7 | 92.5 | |

| 1270 | 94.7 | 93.1 | |

| Dry – Fired Shrinkage | 1250 | 9.85 | 9.15 |

| (%) | 1260 | 10.15 | 9.30 |

| 1270 | 10.20 | 9.35 | |

| Linear Thermal | 20-500°C | 0.38 | 0.42 |

| Expansion (%) | |||

| Loss on Ignition | 1250 | 11.08 | 5.30 |

| (%) | 1260 | 10.81 | 5.30 |

| 1270 | 10.88 | 5.29 |

Natural Calcium Phosphate – Lower Sagging

- Sagging The previous slide demonstrates how using a natural

calcium phosphate helps to reduce the deformation in a

body compared with one using synthetic calcium

phosphate. This helps to explain why the Korean and

Japanese bone china producers have gradually changed to natural calcium phosphate in their bone china formulations.

Samples for Testing

Representative – GCM have appointed KAROPAK as representatives in Türkiye with samples of wet ground and dry ground calcium phosphate available for trials.

The wet milled material is supplied at 78% < 14 Microns (400’s mesh)

The dry milled powder is supplied as a 325’s mesh powder with maximum 5% retained on a 45µm sieve