Mantec Bullers Rings

What are Bullers Rings?

• Mantec Technical Ceramics, with its HQ in Stoke-on-Trent in the heart of the UK ceramics region, is the home of the globally renowned and

industry standard Bullers Temperature Control Devices. Bullers Rings are essential for reliable monitoring of ‘heat work’ or ‘heat energy’ in

a kiln or furnace. Heat work is the effect of temperature over time or how well ‘cooked’ or ‘processed’ ceramic products are.

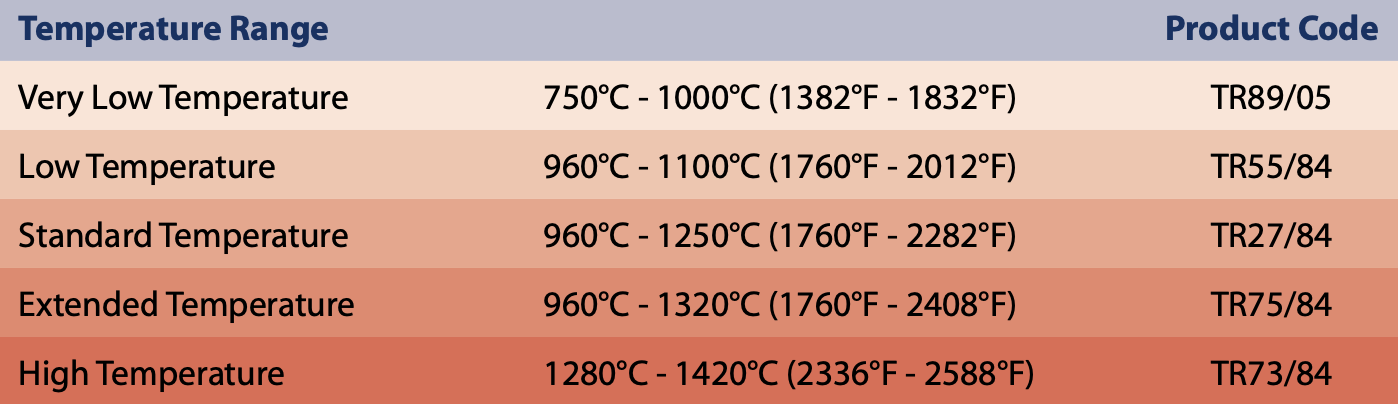

• Bullers Rings operate within a full range of firing temperatures from 750°C to 1420°C (1382°F to 2588°F)

The most common applications for Bullers Rings are in the firing of:

- Heavy Clay (Bricks & Roof Tiles)

- Sanitaryware

- Tableware

- Wall/Floor Tiles

- Refractories

The Benefits of Bullers Rings

- Bullers Rings are an essential part of any Quality Assurance System to ensure the accurate firing of ceramic

- Bullers Rings experience the same ‘thermal journey’ as your ceramic ware so are an early indicator of ‘under fired’

- Bullers Rings are sensitive to changes in ‘Heat Work or Heat Energy’ and their contraction will depend on the combination of temperature, rate of firing and length of soaking Thermocouples alone cannot and will not provide you with this vital information!

- Bullers Rings offer a rapid, low-cost, consistent and reliable method of accurately monitoring kiln performance and aid in establishing optimum firing regimes that:

Step-By-Step User Guide

1 - Selection

Select the most appropriate Bullers Ring type, whose central temperature spread is nearest to your kiln’s peak firing temperature.

2 - Positioning

The aim of the positioning is to establish an accurate map of overall heat distribution and ensures that heat work is monitored throughout the whole of the kiln.

Position the Bullers Rings in a number of different locations throughout the kiln and alongside the product to be fired in accordance with a pre–determined

plan (A typical example is shown below). Mark the corresponding position numbers onto the Bullers Rings.

3 - Measuring

Once the kiln firing has taken place and the Bullers Rings have reached ambient temperature, remove them from the kiln car.

Insert the fired Bullers Ring between the two converging guide rails of the enclosed Plastic Vector Gauge (TR300) until it stops. Take the corresponding Bullers Ring Value (BRV) reading from the top of the ring against the engraved scale.

The Plastic Vector Gauge (TR300) is ideal for short- term use but the alternative and more durable gauges

– Long Life Adjustable Brass Gauge (TR100) or Metal Vector Gauge (TR200) – should be purchased for more regular long term use. Contact Mantec Technical Ceramics or your local distributor for further information on these other gauges.

NOTE: It is not necessary to measure the size of Bullers Rings before they have been fired as these measurements are meaningless and can only lead to unnecessary confusion.

4 - Recording

Record the fired Bullers Ring’s BRV number onto your kiln record sheet against the position in which it was placed inside the kiln.

Mantec recommends that kiln firing results are always recorded in terms of the Bullers Ring Value (BRV) reading obtained by using one of its Bullers Rings Gauges. The BRV reading is the simplest and by far the easiest and quickest way of recording and comparing firing results as it enables you to record your kiln’s heat work (the action and effect of temperature over time on firing a ceramic product) as a single easy to compare number.

This recommended method of recording fired Bullers Ring results thereby avoids the confusion that can invariably be caused when comparing an approximate ‘ring temperature’, converted from the BRV reading using temperature correlation tables, with the localised kiln setting temperatures measured by thermocouples as this is rarely a like-for-like comparison.

5 - Comparing

Bullers Ring results should be compared against historical data, where acceptable results and norms have been determined for each Bullers Ring type and product fired.

If Bullers Rings are being used for the first time, acceptable minimum and maximum shrinkage results – based on the BRV reading in conjunction with the final quality of your fired ceramic product – need to be

determined over a number of firings. These results then become your company’s unique acceptable standard or norm for comparison against future firings.

Any Bullers Rings shrinkage results that deviate significantly from the accepted standards or norms will highlight quickly that corrective action may be required to ensure the correct product quality.

6 - Interpreting Results & Taking Corrective Action

All kilns and furnaces are different and there is no single remedy for under or over firing. The condition of the kiln and the product being fired should both be checked for changes and modifications should only be carried out by suitably trained technicians.

Mantec Technical Ceramics has an experienced technical support team available to help with any queries on the useof Bullers Rings but generally:

1. Low readings (under firing) indicate that less heat work has taken place, either locally or overall. Possible causes are:

- Peak temperature not reached locally

- A leaking temperature around the kiln door or kiln car seals

- An reduction in time at peak temperature or insufficient soak time

- An increased kiln loading density (Reduced air flow)

The corrective action will be specific to the individual kiln, but typical areas to check & investigate are:

- Kiln elements (electric kiln) Burner ratio (gas kiln)

- Kiln seals Damper seals

- Kiln lining Kiln pressure may be low

- Heat input pattern

2. High readings (over firing) indicate that more heat work has taken place, either locally or overall. Possible causes are:

- An increase in peak temperature locally

- An increase in time at peak temperature

- A reduced kiln loading density

The corrective action will be specific to the individual kiln, but typical areas to check & investigate are:

- Burner operation

- Damper operation

- Kiln pressure may be high

- Variation in kiln loading density

- Thermocouple position may have moved

- Policeman thermocouple failure

7 - Calibration

Once you receive a new batch of Bullers Rings, it is necessary to calibrate them against your existing batch under your own firing conditions. By calibrating between different batches of Bullers Rings, you are able to maintain meaningful records of your kiln performance over days, weeks, months and years. For further information on calibration, please refer to our

website: https://mantecrefractories.com/bullers-rings/

Scan this QR Code to download the following additional information and technical assistance from Mantec’s website:

- Frequently Asked Questions

- Temperature Correlation Charts

- Bullers Ring Gauge User Guides

(TR100, TR200 & TR300)