Elastomer For Molds

1. NATURAL 1:1 55A

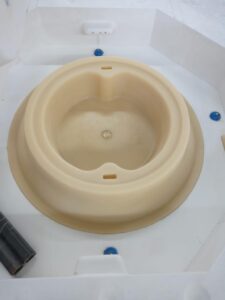

It has good moisture resistance. A solvent-based mold release can be used in Mother molds. We recommend the pouring stage 1:1 mixing ratios in two different containers with mixing for 2 minutes. The mold can be opened after 24 hours. The product that you mold is 55 shore ,the color is beige and has high strength. Excellent results are obtained in especially superficial molds, for example in large sinks.

When the ceramic production mold casting starts, no soap and petrolium based products are recommended to be used on the polyurethane product. The mold release agent should be water-based.

2. NATURAL 1:1 45A

It has good moisture resistance. A solvent-based mold release can be used in Mother molds. We recommend the pouring stage 1:1 mixing ratios in two different containers with mixing for 2 minutes .The mold can be opened after 24 hours. The product that you mold is 45 shore ,the color is beige and has high strength. Excellent results are obtained in especially deep parts, such as toilet molds.

When the ceramic production mold casting starts, no soap and petrolium based products are recommended to be used on the polyurethane product. The mold release agent should be water-based.

3. HT RED 1:1 45A

A solvent-based mold release can be used in Mother molds. We recommend the pouring stage 1:1 mixing ratios in two different containers with mixing for 2 minutes .The mold can be opened after 24 hours. The product that you mold is 45 shore ,the color is red.

When the ceramic production mold casting starts, no soap and petrolium based products are recommended to be used on the polyurethane product. The mold release agent should be water-based.

4. NATURAL 1:2 55A

It has good moisture resistance. A solvent-based mold release can be used in Mother molds. We recommend the pouring stage 1:2 mixing ratios in two different containers with mixing for 1 minutes . this product has a special, very fast gelling and curing time, so we recommend partial casting for high volume castings. The mold can be opened after 24 hours. The product that you mold is 55 shore ,the color is beige and has high strength.

When the ceramic production mold casting starts, no soap and petrolium based products are recommended to be used on the polyurethane product. The mold release agent should be water-based.