Innova Teco Kiln Revestements And Rollers Treatment

TECO-COMPONENTS

TECO-COMPONENTS, S.L.U is a leading manufacturer company specialist in high temperatures and thermal insulation. Being a specialist and a leader means standing out in the technological and innovative field.

Our 35 years of experience, position ourselves as absolute leader in our sector.

TECO-COMPONENTS, S.L.U is a leading player in the high temperature sector, with 30 registered trademarks and 6 patents. Our mission is to offer thermal, anti-chemical attack, anti-condensation and energy saving solutions.

We count with 8000 m2 facilities, which include our own Technological Research and Innovation center.

The production of all our references is our own. Thirty-five years ago, we have started the first technical treatments for ceramic kilns, providing two great solutions to the ceramic sector: the end of chemical attack in kilns with a rapid application and the elimination of condensation forever.

Since then, we have treated more than 1000 ceramic kilns around the world.

Our philosophy, INNOVATION, quality and service

INNOVA-TECO is internationally recognized as a pioneer company in the production of ceramic REVESTEMENTS, offering a complete variety of products with the highest quality and full cooperation with each and every one of our clients. We provide complete and specific solutions to the problems that arise inside the KILNS during the firing of tiles.

We have an experienced human team and the most advanced technologies, which is why we have the capacity to also offer a flexible and effective service wherever the client is, aware at all times of the value of time ,face to a production problem.

Selected raw materials of high purity are used for the exclusive manufacture of our revestments, for refractories and ceramic kilns.

Only by doing different things we have positioned ourselves as leaders in our segment.

Our main suppliers are located in Japan, New Zealand and South Korea.

Our products, as well as the typology and uses, develop and change over time. However, the quality of our service remains as its essence since the first day after almost four decades.

In addition our products, are present in the main international markets and has a properly articulated structure of agents to provide constant solutions and technical advice anywhere in the world.

Only by doing things differently

we are able to move our company and our industry forward

In our own laboratories we carry out the constant development of new and innovative products that adapt to the new needs that constantly arise from each of the sectors where our products can be applied. At the same time we attend to the individual demands of our clients to offer specific solutions in a short period of time.

In our own KILNS we carry out the most complete tests, taking our revestements to temperature limits of up to 1700ºC.

All our products are tested before delivery, so that nothing is left to chance.

CERAMIC COMPANIES IN THE WORLD USE OUR REVESTEMENTS

The most important manufacturers worldwide of tiles and monostatic KILNS, use our products in their kilns for more than 25 years.

Important ceramics used to have to replace the firing areas in their kilns every three years. For 25 years, using our revestements, they have never had to replace a wall in their kilns again. The same occurs for condensation, as their kilns are free of condensation and their percentage of first is higher.

Likewise, important kilns manufacturers worldwide, after start treating their new kilns with our range of revestements before deliver, had experienced that their customers have reduced maintenance inside the kilns by more than 95%.

REVESTEMENT R5000

The R-5000 revestements has been designed and formulated to avoid condensation problems in ceramic kilns.

With a simple intervention of our R-5000 revestements you will end forever the condensation problems that occur in the kiln, thus elimi- nating the number of problems that this entails.

The condensation is produced by polluting agents that adhere to the vault and that after a few months are detached and deposited on the tile causing innumerable casualties.

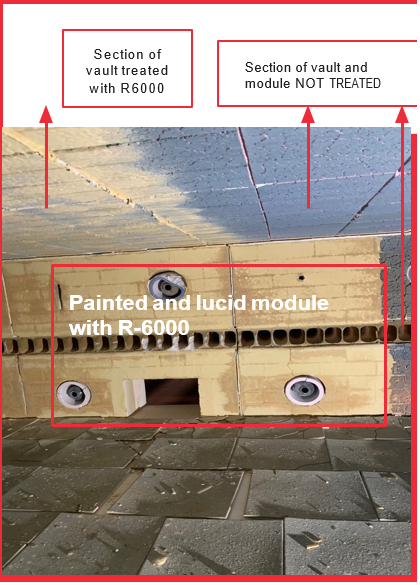

REVESTEMENT R6000

The R-6000 revestement will provide you with safety and optimal production conditions and the best protection for the refractory of your kiln.

The new ceramic products of high technology and design require high cooking temperatures and special chemical compositions, both in base and in enamels. The mixture of these factors leads to premature wear of the kiln refractory that causes indecencies in production, unscheduled and continuous stops and high repair costs.

The revestement has been developed taking into account the indicated production conditions and its main competitive advantage lies in the fact that it is not necessary to replace the refractory of the kiln in cases where the kiln is already chemically attacked.

By this way, we will avoid the expensive stops to make the new walls because the existing ones will be used. In case of new kilns in which R-6000 is applied on new refractory, it will protect it from chemical attack and contaminants, having this way the kiln in optimal conditions for life. It will only be necessary to simply maintain the affected areas every year, when making the stops. In case of new kilns in which R-6000 is applied on new refractory, it will protect it from chemical attack and contaminants, having this way the kiln in optimal conditions for life. It will only be necessary to simply maintain the affected areas every year, when making the stops.

Recover your kilns in poor condition with the best existing treatment in the world. With the product R-6000 Mortar, 10 modules can be re- covered from the cooking area in a single day. Unmatched product. Avoid the high costs of building new modules.

The construction of a new module involves a lot of work and high costs for the company, as well as production losses and discomfort of dirt in the plant during the duration of the work.

With our R-6000 mortar save up to € 200,000.00 per job and reduce your works to one day.

Examples of what our R-6000 mortar is capable of doing

BEFORE APPLICATION

AFTER APPLICATION

REVESTEMENT R8000

It is an ideal material for the protection of:

– Area around the burners.

– Donuts that protect the burners.

– Firewall plates.

– Low areas of the kilns where walls and kiln roof are made of Ceraboard plates.

– For special applications: such as blanket gluing in the cooking area and protector on top of the R-6000.

REVESTEMENT R9000

The R-9000 revestement has been formulated exclusively to treat cordierite vaults in poor condition, vaults that suffer strong chemical attacks and are extremely contaminated.

With a quick application, the kiln will recover the appearance of new, clean and increase our percentage of first by avoiding points of contamination on the ceramic pieces.

The R-9000 revestement is capable of adhering on any surface, leaving these vaults in poor condition as new and radically stopping the chemical attack, thus avoiding the replacement of them, avoiding high costs and loss of production days.

REVESTEMENT R10000

New generation revestement formulated exclusively for application in kilns treated with R-6000. This product will be applied on the surface already treated with R-6000.

It is the same as with the R-8000 revestement, as it is very resistant to high temperatures and chemical attack (2500 ºC), but with the difference that it absorbs the temperature and radiates it. It will help us reduce temperature differences in kilns with wide channels.

In addition to providing energy savings once applied to the R-6000, it transforms the refractory of the kiln into indestructible, completely eliminating maintenance inside.

To apply in kilns treated with R6000 or if your kilns are already many years old and have been exposed to continuous production changes and are in an advanced state of deterioration, you can keep them productive and in perfect condition with the most innovative application. In just three days we will gain your kiln again and leave it in an unrecognizable state to continue working safely.

6 - Interpreting Results & Taking Corrective Action

It is a chemical anti-attack material with a maximum working temperature of 1850ºC. It can be applied on ceramic fiber surfaces, fire plates or similar.

With this material we will protect the fiber plates or plates in the entrance of the kiln to avoid contamination and erosion of the area, thus disappearing the dust.

Ideal material to apply to the firewall plates, as it prevents them from bending or breaking. The plates are not chemically attacked, offering safety of use from stop to stop.

Advantages of treating plates with the P-50000 treatment:

– Withstand high temperatures.

– Very resistant to chemical attack.

– They don’t bend

– Resentful to erosion

– Dust free

– Very resistant to thermal shock

– Prevent contamination

– Not toxic

7 - Calibration