Robots & Pressure Casting

I- Pressure Casting Equipment

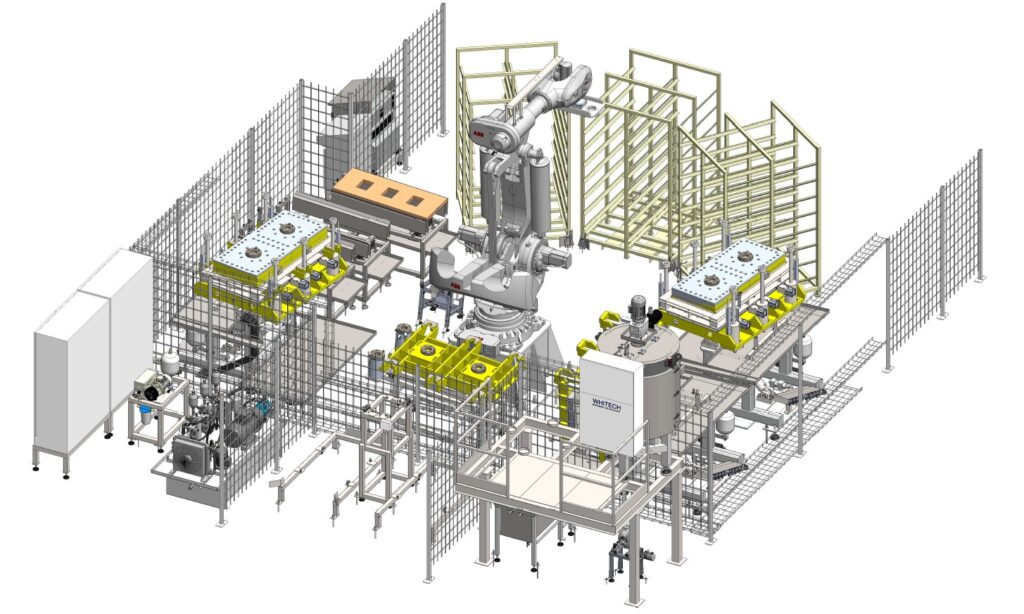

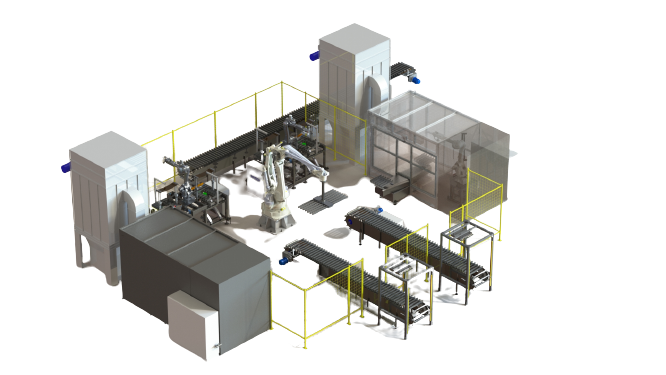

COMPACT CONCEPT

Drivers of Whitech’s technology development

- Mechanically simple machines, to prevent possible damages

- Rapid and automatic mold change, from 6 to 15 minutes for 1 mold change while others are casting

- Centrality of the robot, apart from keeping the mold closed, the robot performs all the needed activities

- Modular technology, machines can grow with the factory grow

- Maximum casting pressure 15 bar

- Easy and reduced maintenance

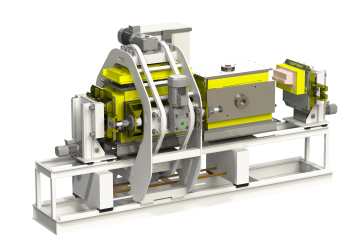

I-1a CBR

Compact® pressure casting unit for WCs

With this equipment complex bowls are made simple

– Suitable for Stick on rim bowls, Smart toilets and One-pieces production

– Every machine can produce different products

– Fully automatic casting and demolding of pieces

– Rapid and Automatic Mold Change made in less than 15 minutes

– Operates with Pipeless molds technology

– Can be provided with or without finishing station

– Cost effective: reduction of machine cost compared to similar robotic units

for more information visit: Learn more

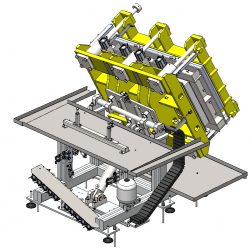

I-1b CWB4

- Suitable for Washbasin, Tanks, Columns, Lids, Shower tray and Squat toilets production

- It is possible to cast multiple materials (Vitreous China and Fine Fire Clay)

- Every machine can produce different products

- It is possible to cast and demold with the press inclined between 0 and 90°

- Fully automatic casting and demolding of pieces

- It is possible to cast simultaneously multiple materials (Vitreous China and Fine Fire Clay)

- Rapid and Automatic Mold Change made in approximately 5 minutes

- Operates with Pipeless molds technology

- Cost effective: reduction of machine cost compared to similar robotic units

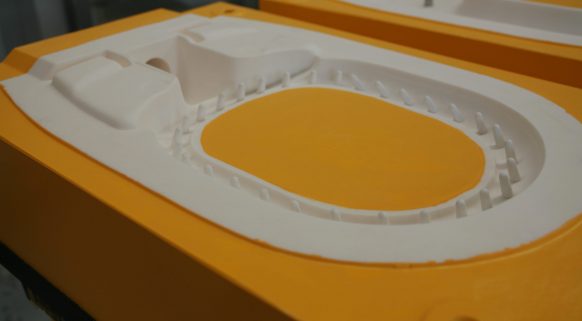

3. A Resin Mold Making

In whitech, we use CAD/CAM process on model making to have the highest quality pressure casting molds. A virtual model is generated to aprove all sizes, curves, connections in details. Only then the model and mould making starts. This method makes Whitech moulds significantly precise.

Whitech mold making studio works with the quality control and precision philosophy at every step of production of each individual piece to construct the whole unit in the best way. More than thousand molds were produced and distributed worldwide to most reputable producers successfully. We target long life time, optimum speed of de-molding and humogen air flow throughout the mould body.

for more information visit: Learn more

4. Porous Resin For Pressure Casting

WHITECH AL08-1 is the Casting Resin System for the manufacture of high stability pressure casting molds. Easy to apply procedure and superb resin combination helps to obtain homogeneous air flow throuout the resin mold. Whitech formulated this resin to have good tolerance in various conditions and with most forgiving features for problem free casting. With these properties clogging of mold pores are prevented, hence the longest possible casting cycles are achieved. With Whitech resin shrinkage is kept in minimum figures so most of the cases it is negligible. Therefore the model and the mold could be considered almost the same size.

for more information visit: Learn more

5. Dryers

In the production of sanitary ceramics, the drying of the pieces is fundamental to achieve a high level of quality. Careful control with the aim of achieving fast and uniform drying is one of the main features of our products. Whitech designs and manufactures continuous and static dryers.

for more information visit: Learn more

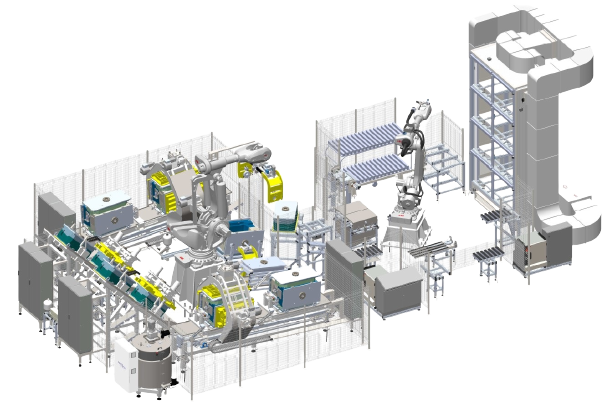

6. Robotic Glazing Lines

The WHITECH robotic glazing system for sanitary ware represents a new concept that combines maximum flexibility with complete automation of the entire process, thanks to the high modularity and integrability of the various components.

A mechanically simple line adaptable to any type of plant requirements

for more information visit: Learn more

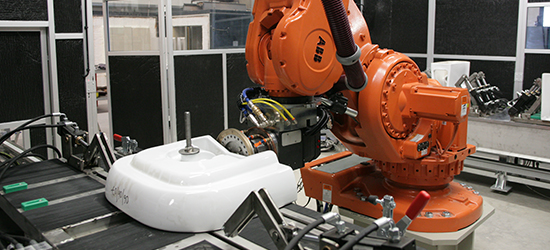

7. Robotic Grinding Cell

Multifunctional robotic grinding and cutting unit for any type of sanitary ware with double charging station.

for more information visit: Learn more